Surviving Pump Ripple

Issue

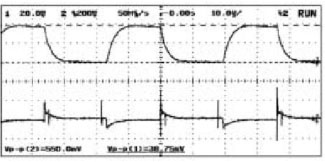

A Tier 1 manufacturer of hydraulic systems was encountering problems with high levels of pressure ripple due to impeller pump. Their existing configuration utilized sensors based on older technology which resulted in premature catastrophic unpredictable failure requiring part replacement.

Solution

Hydra-Electric worked with the manufacturer to understand the extent of the pump ripple problem. We were able to deliver a sensor based on our breakthrough thin film technology that does not fatigue or break during the full pressure ripple operation of the unit. The solution eliminated the possibility of failure due to pump ripple or pressure extremes.

See our white paper, “Lightning Induced Transient Susceptibility” in the Knowledge Center.